Plastic-type is a crucial element in our daily lives for many years, from packaging components to playground products, and healthcare devices to automotive parts. Even so, the production of plastic products is traditionally covered with approaches such as injections molding, blow molding, and thermoforming. However nowadays, we will investigate the ability of Rotomolding, that has revolutionized plastic material production featuring its exclusive qualities and revolutionary strategies.

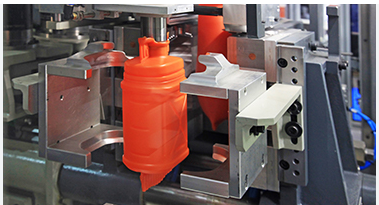

Rotomolding, also called rotational molding, is a relatively new manufacturing approach that concerns the warming of your hollow mildew on an axis, then incorporating the required substance. The fungus will then be rotated, creating the substance to equally jacket the inside the mold as it cools down and solidifies. This procedure generates a seamless, hollow item, which is often made in a selection of sizes and shapes, from little toys to huge tanks.

Among the important advantages of Rotomolding is its ability to use a wide range of supplies, such as PVC, nylon, and polyethylene. This simply means creative designers possess the flexibility to generate custom made items with special qualities, for example Ultra violet opposition, chemical level of resistance, weather conditions amount of resistance, and flame-retardancy. Additionally, Rotomolding is well-suitable for generating prototypes or simple manufacturing goes, that may minimize costs and speed up the development method.

Another main benefit of Rotomolding is its cost-performance. As opposed to shot molding or blow molding, which require considerable upfront investments in molds, Rotomolding only requires a single fungus, which is often reused for a large number of cycles. This results in reduce tooling expenses, creating Rotomolding an expense-successful method for making sizeable or intricate merchandise.

As mentioned earlier, Rotomolding is fantastic for making big and complicated styles. Since the materials is distributed equally all over the mildew, it assists you to create hollow items that will be challenging or impossible to manufacture using other methods. This process also provides for heavier walls as compared to other techniques, that will make goods more durable and resistant against wear.

The unique qualities of Rotomolding allow it to be particularly designed for producing a selection of merchandise, which includes water tanks, garden furniture, play ground gear, medical gadgets, and agricultural gear. As being the interest in personalized and sturdy products expands, the use of Rotomolding has become much more wide-spread in several businesses.

quick

To conclude, the art of Rotomolding has transformed the way we think of plastic manufacturing, giving a selection of benefits and options that conventional methods cannot go with. It is an exciting and innovative method that features a significant long term in different industries’ producing functions. So, it’s definitely worth checking out the ability of Rotomolding and the way it might benefit your business’s requirements, whether it’s via quick prototyping or huge-size production goes.